Indoor Asset Tracking Frequently Asked Questions

- bensturgess1

- Nov 4, 2024

- 4 min read

Updated: Nov 26, 2024

What Is Indoor Asset Tracking?

Indoor assets tracking is simply a system or solution that allows you to track an asset’s location, movement and more within an indoor space such as a warehouse, manufacturing plant or factory.

Asset tracking is not just limited to location however, you can also look at the asset’s movement, runtime (if it is on or off), temperature and environmental data (is the item being subjected to environmental pressures).

What Is an Asset?

An asset can be anything that you may want to track in the workspace. This could be tools, parts, composites, equipment (forklifts, pallets, pump trucks) or even the product themselves. A growing number of companies in sectors such as aerospace and automotive are turning to asset tracking to give them greater visibility into their Work In Progress (WIP) process to see where holdups and bottlenecks are occurring in their manufacturing process.

What Method of Tracking Is Best for My Assets?

This will be determined by exactly what you are looking to track with your assets. As mentioned above, asset tracking is not just about location, so if you are looking to track the run time data on your stationary machines, then you wouldn’t need to know it’s location data through GPS or LoRa, but rather how often it is being used through a tracking tag’s accelerometer and local connectivity to a tag base unit.

How Do You Track an Asset in A Building?

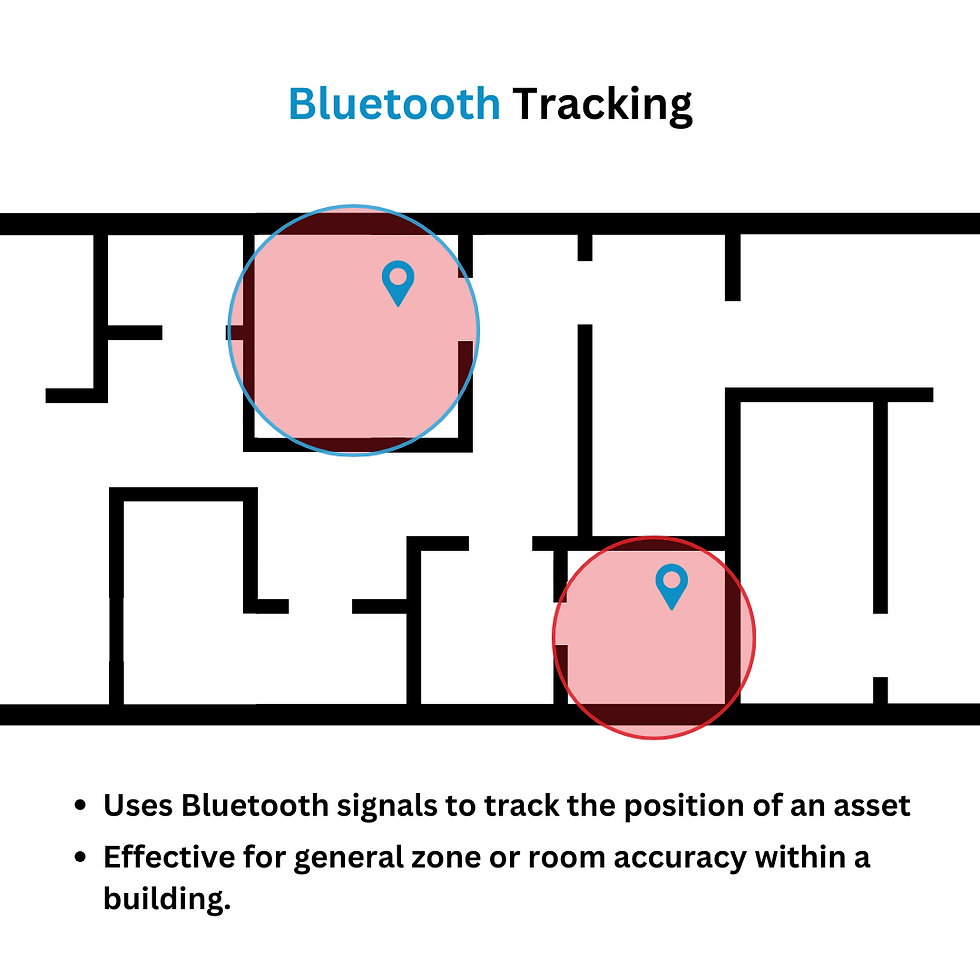

Indoor asset tracking can be achieved using several types of technology including Ultra-Wide Band (UWB), Bluetooth, Wi-Fi, and GPS satellite tracking. The choice of technology for tracking depends on the specific tracking needs, as well as the desired level of accuracy and frequency. Below is a brief overview on what each technology can do.

Ultra-Wide Band (UWB) – UWB is a radio technology that can use a very low energy level for short-range, high-bandwidth communications such as location. The distance is around 100-150M (398-492ft) but can accurately pinpoint an asset to within 30cm. It is most commonly found in iPhone’s and more recently in Apple Tags.

Bluetooth Low Energy (BLE) – is similar in design to UWB but can have a tracking distance of around 10m (33ft). It is also found in mobile phones to connect external peripherals such as headphones or smart watches. It has the ability to send data in a wireless fashion without the need for cables. Bluetooth asset tags such as Pathfindr’s ones, can have a battery life of up to 5 years.

LoRa & GPS – both are predominantly used for external tracking as they can cover miles (and in most cases globally). LoRa simple stands for Long Range and has very low power consumption.

What is Tool Tracking?

Tool tracking has become more commonplace in factories, manufacturing plants and indoor locations across the UK.

Tool tracking allows you to not only locate your tool within the indoor location, but also see the environmental and run-time activity using Pathfindr’s asset tracking and intelligence platform. A simple to use, web interface allows you to see your tools real-time data, even if your factory is the other side of the world.

Asset tracking and management systems can be used to create alerts for tools based on varying factors, such as run-time, location, temperature, or dew point. All of which are fully customisable in the online portal.

The use of high-value shared equipment can be uncoordinated, causing increased costs and errors from inefficient or incorrect use of equipment.

Pathfindr’s tool management module ensures important maintenance and calibration schedules are met and tools are staged and used correctly, improving quality and use.

Easily create alerts for tools or equipment that are due (or overdue) maintenance or calibration but still in use.

Use dashboards of actual tool use over time and within

Defined spaces to identify better ways to stage, manage and coordinate equipment.

Trigger maintenance based on actual tool usage to reduce costs and improve quality.

We work with several aerospace and aviation manufactures who utilise Pathfindr’s Tool management systems to help protect against Foreign Object Damage (FOD) by ensuring tools are not left in a planes body while work is ongoing. Not only can this save businesses time and money by knowing where high-value tools are located should the go missing, but also ensuring that upon work being finished, no tool is accidentally left in in bodywork or fuselage, thus reducing delays and expensive grounding of planes to remove the foreign object.

What is Work In Progress (WIP) Asset Tracking?

Indoor asset tracking is not just about the location of equipment and tools but can also allow you to see the status of your WIP (work in progress) line. By analysing your WIP, you have greater visibility on bottlenecks, holdups, and areas of that are not running as efficient as you want in real-time. By placing an asset tag onto the product at the start of the assembly line, manufacturers can see which areas of the process are slowing down or even stopping production.

Indoor tracking has numerous real-world benefits to businesses across all sectors and is becoming increasingly important for businesses looking to get real-time data and insights into their assets. Pathfindr can assist you with all your indoor tracking asset needs.